Sustainability

Why are we helping?

Horticycle™ was created by the Tapex Group. Tapex have been supplying protective cropping solutions to Australian & New Zealand farmers for sixty years. Tapex have a long history of taking responsibility for the products they supply at end of life. In 2006 they established the Plasback farm plastics product stewardship scheme in New Zealand. Today, Plasback is still going strong, recycling over 5,000 tonnes off NZ farms annually. www.plasback.co.nz

Tapex Group now owns GreenlifeGRO – leading suppliers of protective cropping plastics to the horticultural sector.

GLG constructs commercial greenhouse and shade structures, helping growers reduce crop loss due to pest and climate challenges, as well as custom protective product solutions to the horticulture industry.

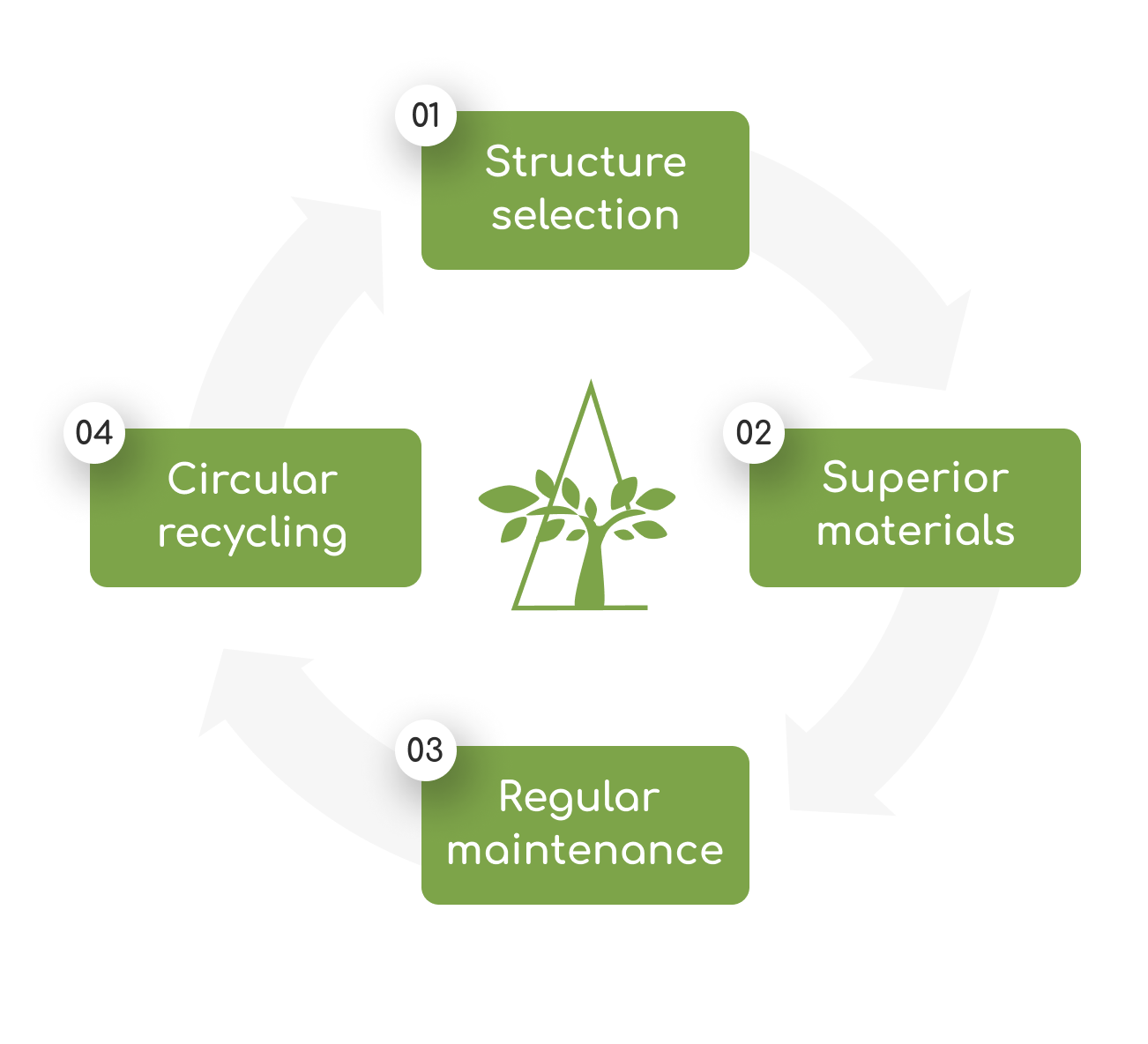

Plastic components are integral to the success of intensive horticulture, but these plastics have a finite productive life. Horticycle has been created to find solutions to recycle these plastics at end of life – and at the same time facilitate solutions for all suppliers to the sector.

Who is helping?

In addition to Tapex Group and GreenlifeGRO, Horticycle is working with other leaders in the horticulture and recycling sectors.

Free Quote Form